Artificial reef design for marine companymarine solutions

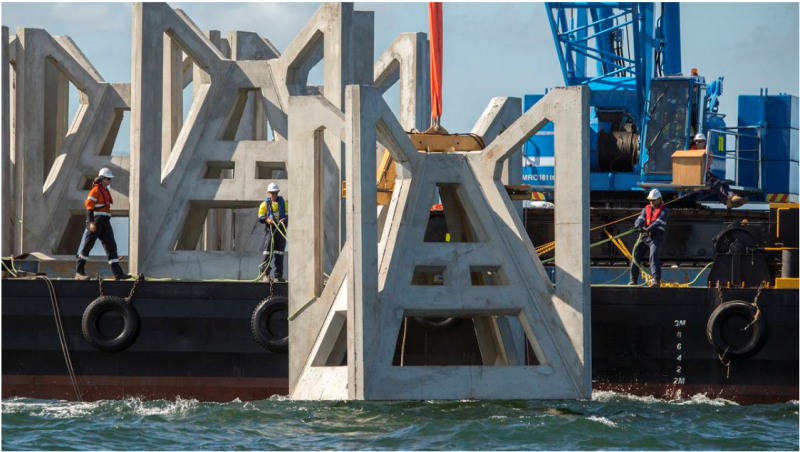

The reef modules weighed 25mT and installed by crawler crane on a flat top barge. The crane could manoeuvre to position and quickly lift and lower modules onto the seabed, thereby saving critical offshore installation time.

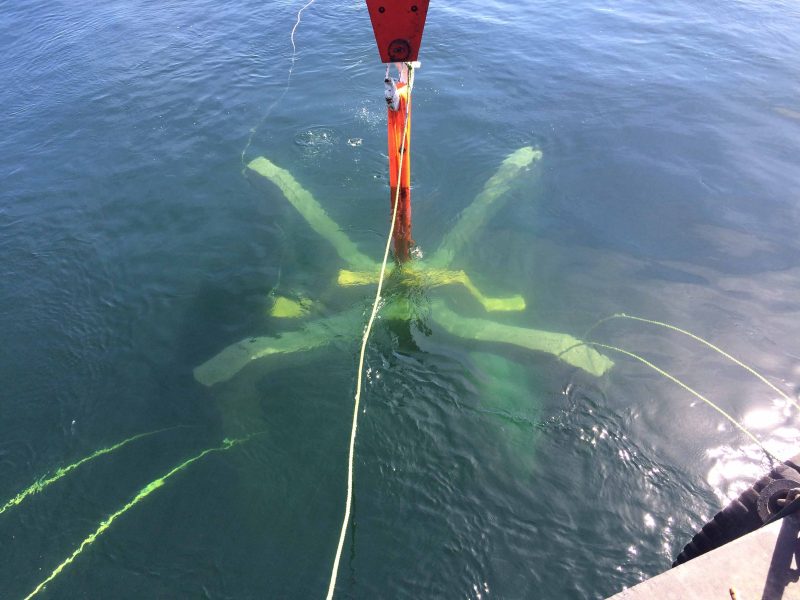

Think Structural designed the modules to use high strength concrete and large cover to meet design life. The module installation incorporated a specifically designed hydraulic lift beam which allowed for quick release upon safe setdown on the seabed. This negated the need for expensive air divers on site and release of the modules was simple and without complications.

challenge

The biggest challenge to the reef pyramids was the complex 3-dimensional shape of the reef modules requiring some innovative design techniques. With very few horizontal or vertical planes this created a unique challenge for the concrete design as well as for the mould design.

solution

Designing a steel plated mould that was not only robust but also easily transportable and could be lifted by a forklift was called for. The solution was a light weight custom made steel plated form with swing bolts attached to the sides to allow for quick assembly. In later modules, the concrete design incorporated fibre reinforced concrete (FRC) thereby reducing the requirement for steel rebar in the design.

results

The complex 3-D shape of the reef module presented many challenges for the mould and the concrete design. Think’s innovative lift beam and mould design achieved all client’s expectations and delivered a reef temple design on time and on budget.